Technology is Here to Stay

Takeaway packaging paper bowls refer to disposable, convenient and hygienic paper containers used in takeout, fast food restaurants and other places. Its production process involves many links, including raw material procurement, pulping, paper making, die-cutting, printing, molding and so on.The following Wuhan Xinhonghai factory produces takeaway paper bowl as an example to introduce its specific production process.

1. Raw material procurement

The main raw materials of takeaway packaging paper bowls are paper pulp and waste paper. Manufacturers usually choose suppliers with low raw material prices and stable quality for purchase. According to the market demand and the production plan, we will reasonably control the raw material purchase volume and inventory.

2. Pulling

Pulping is the process of fibrosing raw materials. Different pulp methods such as chemical pulp, mechanical pulp or mixed pulp can be used. Here, we take the mechanical pulp as an example. Put the raw material waste paper into the slurry tank and add water, and participate in the chemical drugs, through heating, stirring and screening, the fiber is dispersed in the water to form the slurry.

3. Paper making

After the pulp is finished, the pulp is sent into the paper machine for paper making. The paper machine filters out the slurry from the top to the bottom through the rolling simplicity, roller and other devices to form paper. According to the requirements can participate in the paint, resin and so on to increase the quality and waterproof performance of the paper.

4. Module

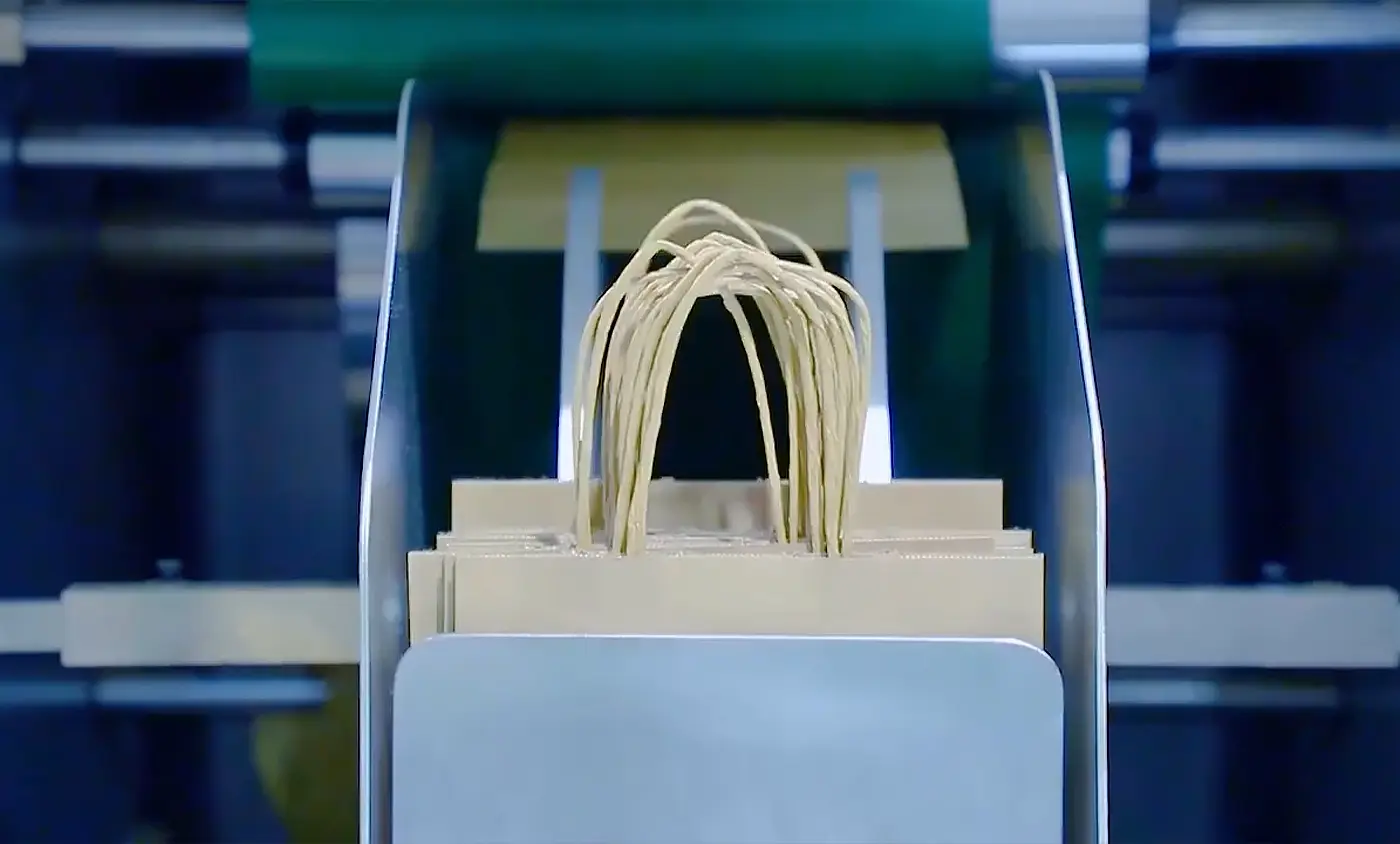

After drying, coating and other processes, the paper strip shape, need to be die-cut according to the size of the takeaway paper bowl. The die cutting machine cuts the paper according to the set specifications to get the corresponding shape of the die cutting billet.

5. Printing

In order to improve the beauty and identification of takeaway paper bowls, manufacturers usually print on the die-cut billet. Ink and plate must be used for printing, the trademark, logo and text of the takeaway paper bowl shall be designed according to the requirements, and the printing press shall be printed according to the set printing scheme.

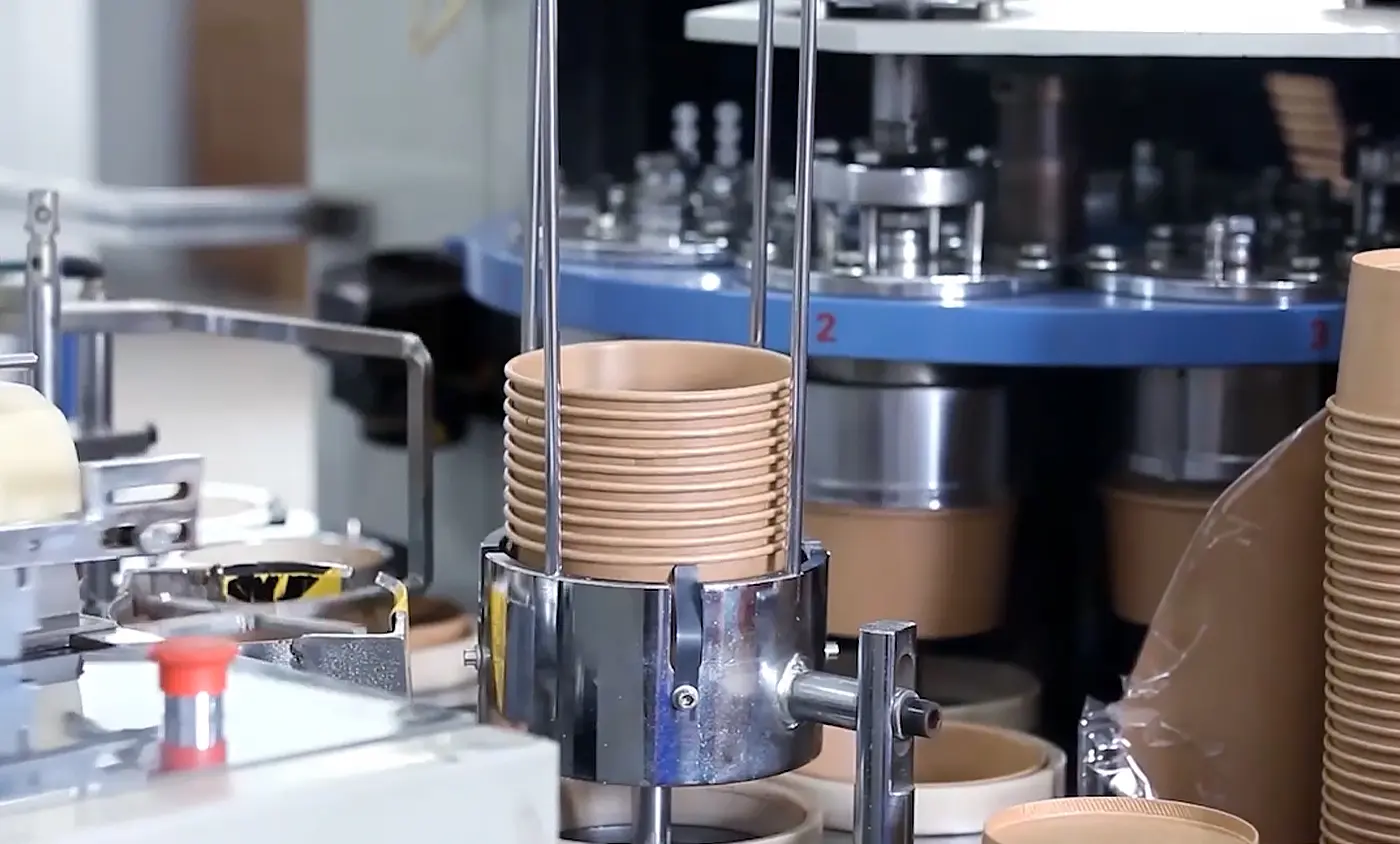

6. Forming

The printed die-cutting billet needs to be formed, usually by automatic molding machine and manual molding methods. The molding machine posts the die cutting billet on the mold at high temperature and high pressure. Manual molding is mainly using manual molding machine for manual curling and bonding process.

Summary:

After the above six links, the production of the takeaway paper bowl was manufactured. Here are the specific data:

Our factory produces takeaway packaged paper bowls, with an average daily output of 50,000 takeaway paper bowls. The main raw materials are waste paper and pulp. Among them, about 30 tons of pulp raw materials and about 20 tons of waste paper are used for production every day. The production process also involves a variety of excipients, such as chemicals, coatings, ink, glue and so on. Relative to the pulp and waste paper, the consumption of accessories is less.

The production process of takeout packaging paper bowl is becoming more and more automated, and the technology of production equipment such as molding machine and printing machine is constantly updated, so as to improve the production efficiency and quality. Take-out paper bowls have gradually become deeply loved by people and become an indispensable part of modern life.